Published: April 02, 2020

UT’s Fab Lab Makes Face Shields for Tampa’s Health Care Workers

On any given day, Emma Quintana is asked to problem-solve on a variety of projects, from an entrepreneur’s prototype to a marketing class’s campaign materials.

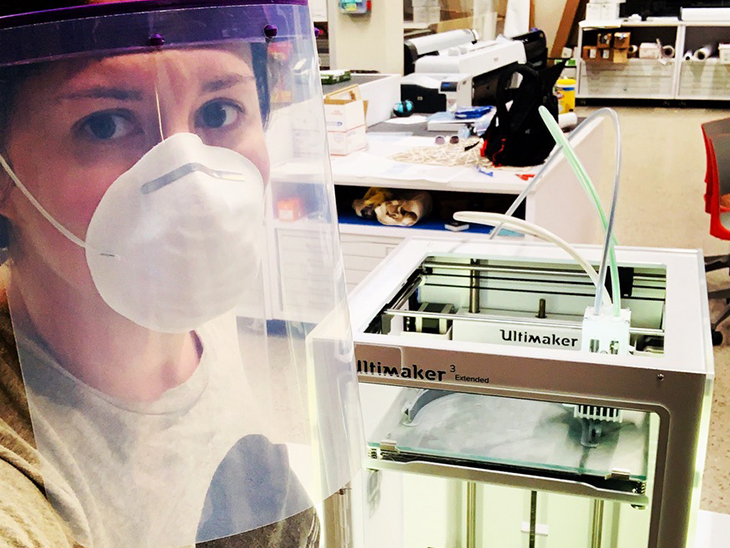

Emma Quintana, coordinator of UT’s Fab Lab, is making face shields for health care workers with materials from the digital fabrication lab. Photo courtesy of Quintana

“I like how every day I don’t know what I’ll be doing,” said Quintana, coordinator of UT’s Fab Lab, a digital fabrication lab (a workshop equipped with tech-enabled tools for students in the arts to foster creativity and innovation) inside R.K. Bailey Art Studios.

So it was no wonder that when UT implemented remote learning in response to the COVID-19 crisis, Quintana started getting creative and is now making protective face shields — visors that wrap around the head and include a plastic shield that is long enough to cover health-care workers' glasses and N95 respirator.

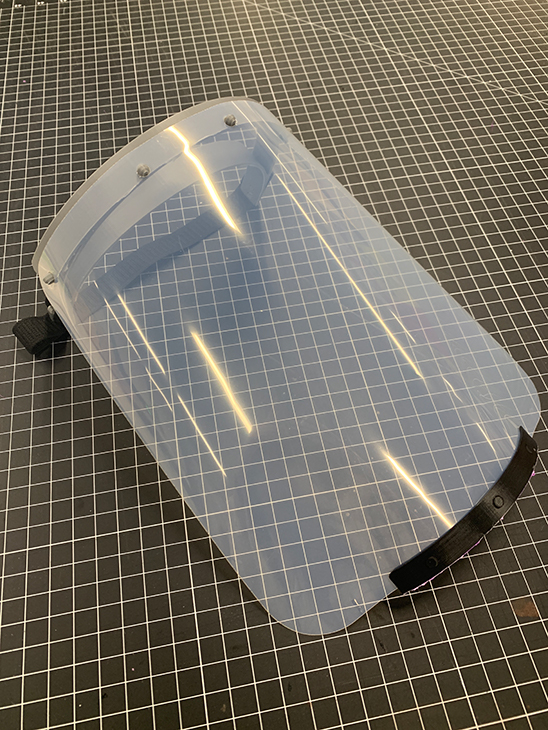

She is using equipment from the Fab Lab: 3D printers to create the shield frame and a laser cutter to precisely cut the clear plastic shield. Then she adds elastic to the back. She was inspired by others in the global Fab Lab community who were sharing instructions on how to print 3D face shields.

Quintana is using equipment from the Fab Lab: 3D printers to create the shield frame and a laser cutter to precisely cut the clear plastic shield. Then she adds elastic to the back. Photo courtesy of Quintana

“There is a thriving open-source 3D printing community, and many makers around the country are working to address the PPE (personal protective equipment) shortages within their local communities,” said Quintana. “These recent shortages and the role local makers are taking by becoming small-scale manufacturers show the flexibility of these spaces and the ingenuity of the making community: arts and engineers working together.”

Since spring break, Quintana has been reaching out to health care workers, testing sites and hospitals to see if the Fab Lab could assist with the shortages.

"During this unprecedented time, we appreciate the outpouring of community support for our health care workers on the front lines," said Dr. Joe Perno, vice president of medical affairs and the vice chairman of the Department of Medicine at Johns Hopkins All Children’s Hospital, which received 100 face shields from Quintana on April 3. "We are especially thankful for the university’s donation because face shields are a vital component of personal protective equipment that keep our staff safe during patient care."

Other recipients include Moffitt Cancer Center, Tampa General Hospital and a COVID-19 testing site, all in Tampa, and AdventHealth Centers.

It takes about six hours from start to finish to create one face shield. Quintana has been utilizing all eight 3D printers in the lab, testing prototypes and refining as she goes. It’s making an impact already.

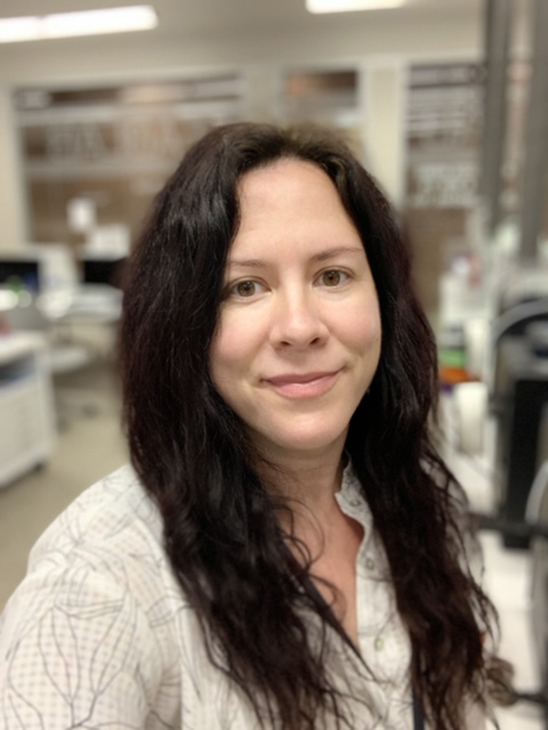

“The appreciation that I've received from the few individuals I've donated to is heartwarming,” said Quintana, who is making the shields in between teaching her courses online. “We are all doing our best for others during this time by socially isolating and modifying our daily routines, our workdays and our academic lives. I'm giving back in my own my way, but so are many others.”

“The appreciation that I've received from the few individuals I've donated to is heartwarming,” Quintana said. “We are all doing our best for others during this time by socially isolating and modifying our daily routines, our workdays and our academic lives. I'm giving back in my own my way, but so are many others.” Photo courtesy of Quintana

While she works alone in the lab on campus, Quintana said she feels far from isolated, since she is in contact with other makers from other institutions regularly.

“It's an amazing feat we are accomplishing, and it gives many of us a way to give back to our real heroes, medical workers,” Quintana said. “The idea that we don't have to wait for factories abroad to deliver these life-saving objects is pretty incredible.”

Have a story idea? Contact Jamie Pilarczyk, Web Writer

Read more UT Life stories